F.A.Q

A steering gear is a machine that helps the driver apply force while turning the steering wheel, thereby reducing the force the driver needs when turning and achieving the purpose of making driving easier and more convenient for the driver. It is mainly divided into rack and pinion steering and worm gear steering. There are roughly three types of power steering devices available on the market: electric motor power steering, rack and pinion hydraulic power steering, and electric hydraulic power steering.

Electric motor power steering starts at the same time when the driver touches the steering wheel

The rack and pinion power steering system has a hydraulic pump beside the engine, and the engine drives the pump to work

Electric-hydraulic power steering is a combination of the former two and is also the best power steering device available on the market today

The structure of the power steering gear is very complex and cannot be repaired by ordinary people. If it is well maintained on a regular basis, it is not very easy to break down. Note: First, you should frequently check the oil in the oil cup and ensure it is not below the lower limit of the dipstick. If the booster loses oil, the pressure pump may be scrapped. Second, change the oil regularly. Third, you mustn’t turn the steering wheel dead. Fourth, try not to turn the direction in place.

The power comes from the engine. There is no other way to assist the truck, only a hydraulic power pump, which is usually installed on the flywheel housing and driven by the crankshaft. It is also installed in front of the engine and driven by a belt, but this kind is usually modified.

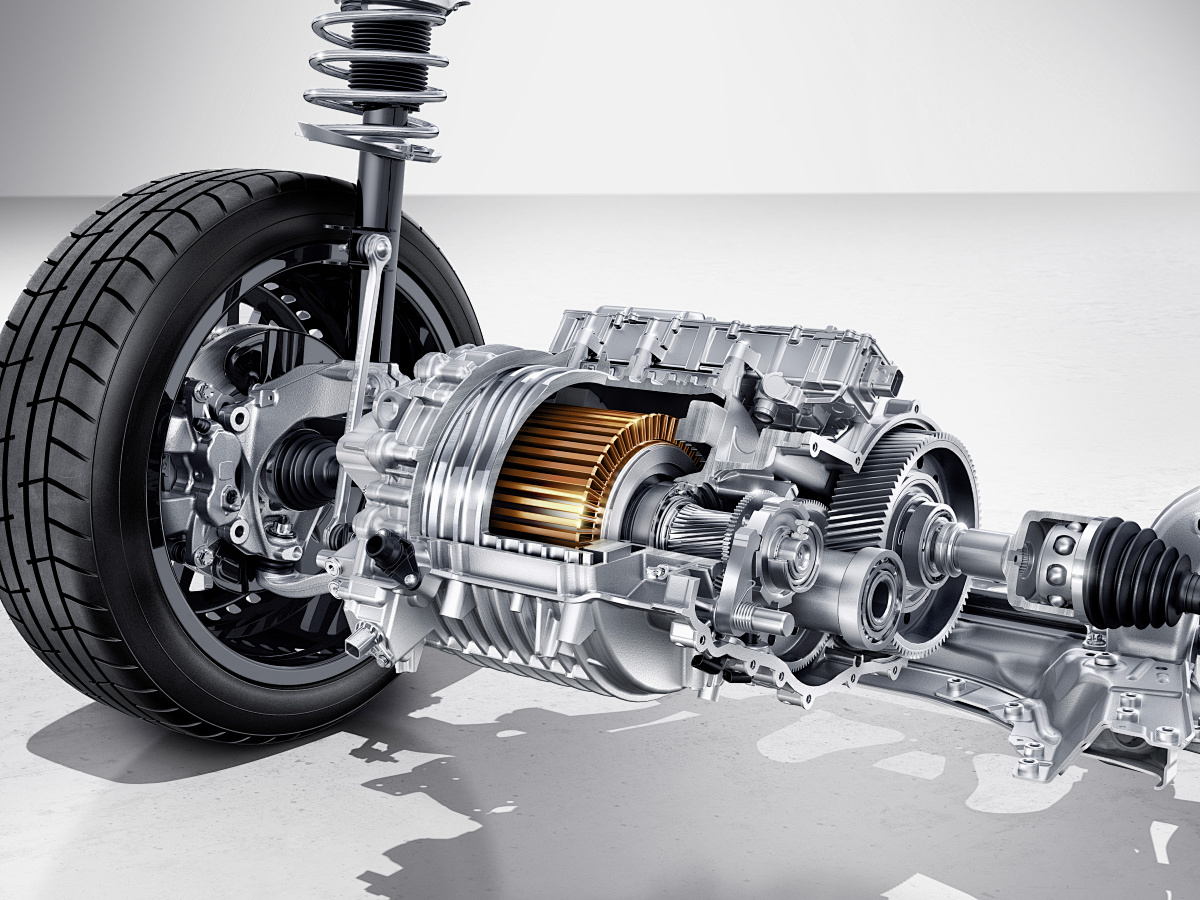

The power steering system is composed of a set of power auxiliary devices added on the basis of the mechanical steering system. The steering oil pump 6 is installed on the engine and is driven by the crankshaft through a belt to output hydraulic oil outward. The steering oil tank 5 has inlet and outlet oil pipe joints, which are respectively connected to the steering oil pump and the steering control valve 2 through the oil pipes. The steering control valve is used to change the oil circuit. The mechanical steering gear and the cylinder block form two working chambers on the left and right, which are respectively connected through the oil passage and the steering control valve.

According to the different energy transmission media, power steering gears can be divided into pneumatic type and hydraulic type. Trucks with extremely large loading weights are not suitable for pneumatic power steering, as the working pressure of the pneumatic system is relatively low (generally not exceeding 0.7MPa). When used on heavy-duty vehicles, the size of its components will be overly large. The working pressure of the hydraulic power steering gear can be as high as over 10MPa, so its component size is very small. The hydraulic system operates noiselessly, has a short working lag time, and can absorb the impact from uneven roads. Therefore, hydraulic power steering gears have been widely applied in various types and levels of automobiles.

According to the different arrangements and connection relationships of the mechanical steering gear, steering power cylinder and steering control valve in the steering device, the hydraulic power steering device is divided into integral type (the mechanical steering gear, steering power cylinder and steering control valve are designed as one) and combined type (the mechanical steering gear and steering control valve are designed together). There are three structural types: independent steering power cylinder and separated type (the mechanical steering gear is independent, and the steering control valve and the steering power cylinder are designed as one unit).

Here, only the hydraulic integral power steering gear is introduced.